In the dynamic world of bakeries and confectionery, having the right packaging is as crucial as the delicious treats inside. A cake box making machine can streamline your packaging process, ensuring your cakes are presented in an attractive and secure manner. But with a plethora of options available in the market, how do you choose the one that best suits your needs? Here's a comprehensive guide.

1. Production Volume Considerations

-

Small - Scale Bakeries: If you run a local bakery with a relatively low daily output, say up to 100 - 200 cake boxes a day, a semi - automatic or even a manual cake box making machine might be sufficient. These machines are generally more affordable, require less maintenance, and can be operated by one or two employees. For example, a manual machine allows for greater flexibility in case you need to produce boxes of different sizes infrequently.

-

Large - Scale Operations: High - volume bakeries or those supplying to multiple outlets need an automated cake box making machine. These machines can produce hundreds or even thousands of boxes per hour. They are equipped with advanced features like continuous feeding systems, high - speed cutting and folding mechanisms, and precise control systems to ensure consistent quality even at high production rates.

2. Box Size and Design Flexibility

-

Diverse Cake Sizes: Look for a machine that can accommodate a range of box sizes. Whether you make petite cupcakes, standard - sized cakes, or large multi - tiered wedding cakes, the machine should be adjustable to create boxes of various dimensions. Some machines come with interchangeable molds or settings that can be easily modified to produce different box sizes.

-

Custom Designs: If your bakery prides itself on unique packaging designs, consider a machine that offers features such as embossing, window punching, or the ability to add decorative elements. This could give your cake boxes a distinct look that sets your brand apart in the market.

3. Material Compatibility

-

Cardboard and Paperboard: Most cake box making machines are designed to work with cardboard or paperboard materials. Ensure that the machine you choose can handle the thickness and quality of the material you plan to use. Thicker cardboard may require a machine with more robust cutting and folding mechanisms to ensure clean and precise results.

-

Eco - Friendly Materials: With the growing emphasis on sustainability, if you intend to use recycled or biodegradable materials, make sure the machine is compatible with them. Some modern machines are specifically engineered to work with eco - friendly materials without compromising on performance.

4. Machine Performance and Quality

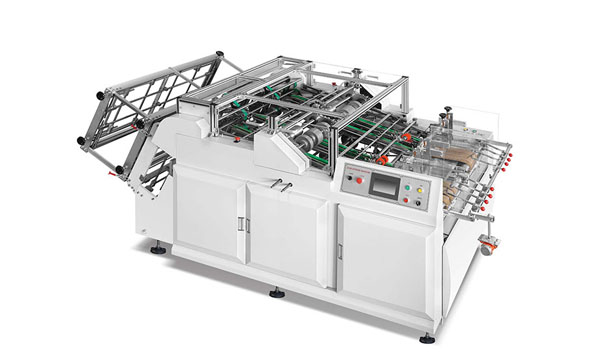

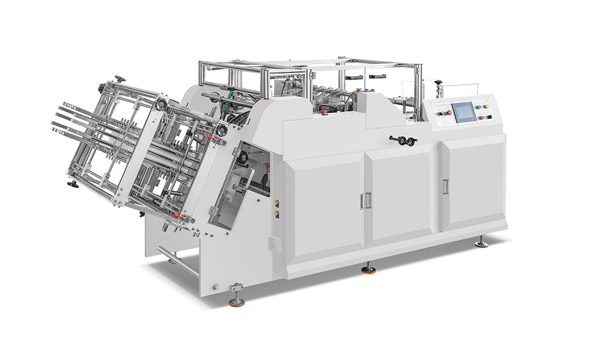

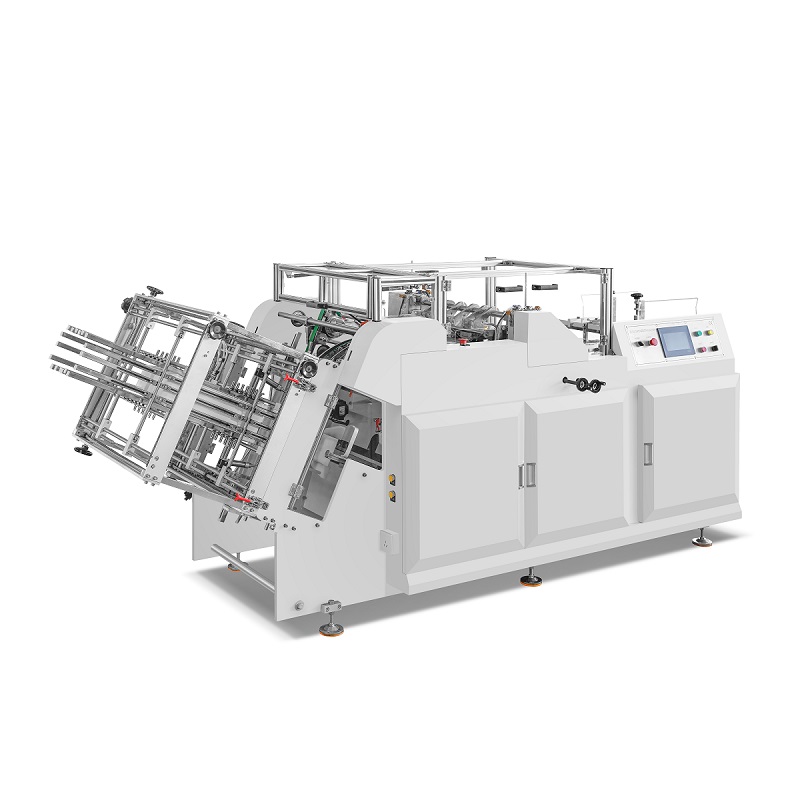

Automatic Cake Box Making Machine

-

Cutting and Folding Precision: A high - quality cake box making machine should produce boxes with clean cuts and accurate folds. This not only gives the boxes a professional look but also ensures that they are sturdy enough to hold the cakes. Check the machine's specifications for the accuracy of its cutting and folding mechanisms.

-

Speed and Efficiency: The machine's production speed should align with your business requirements. Faster machines are great for high - volume production, but they should also maintain quality. Additionally, consider the machine's setup time and changeover time between different box sizes or designs. A machine with quick changeover capabilities can save you valuable production time.

5. Budget and Cost - Effectiveness

-

Initial Investment: Cake box making machines can vary widely in price depending on their features, capacity, and brand. Set a clear budget based on your business's financial capabilities and growth projections. Remember that while a cheaper machine may seem like a good deal initially, it could end up costing more in the long run if it has frequent breakdowns or lower production efficiency.

-

Operating Costs: Factor in the cost of power consumption, maintenance, and replacement parts when evaluating the total cost of ownership. A machine with energy - efficient components and easy - to - access parts for maintenance can help keep your operating costs down.

6. After - Sales Support

-

Warranty: Choose a machine that comes with a reasonable warranty period. A good warranty indicates the manufacturer's confidence in the product's quality and gives you peace of mind in case of any defects or malfunctions.

-

Technical Support: The availability of prompt and reliable technical support is crucial. In the event of a machine breakdown, you need to be able to get in touch with the manufacturer's support team quickly and have them resolve the issue. Some manufacturers offer online support, phone support, or even on - site visits for maintenance and repairs.

7. Reputation and Reviews

-

Research Brands: Look for well - established brands in the industry. Brands with a good reputation are more likely to produce high - quality machines and offer better after - sales support. You can research online, ask for recommendations from other bakery owners, or check industry forums and review sites.

-

Customer Reviews: Read customer reviews and testimonials about the specific machine models you are considering. This can give you insights into the machine's performance in real - world settings, any common issues users have faced, and how satisfied they are with the machine overall.

By carefully considering these factors, you can make an informed decision and choose a cake box making machine that will not only meet your current needs but also support the growth and success of your bakery business in the long term.