Fast food packaging boxes are produced through a series of processes including design, material selection, printing, molding, quality inspection, packaging and shipment. The following is a detailed introduction to the production process:

Design

-

Concept Development: Designers first consider the brand image, target audience and the type of food to be packaged. For example, a fast food brand targeting children may adopt a bright color scheme and cartoon patterns. They also take into account factors such as the size and shape of the food, and whether the packaging needs to have special functions like heat preservation or leak prevention.

-

Digital Design: Using graphic design software like Adobe Photoshop and Illustrator, designers create 2D sketches of the packaging box, detailing the layout of patterns, text, logos and other elements. They may also make 3D renderings to visualize the final effect. After the design is completed, it is submitted to the client or relevant department for review and approval.

Material Selection

-

Paper-based Materials: Common paper materials include cardboard and coated paper. Cardboard is durable and has good shaping ability, making it suitable for packaging burgers and fried chicken. Coated paper has a smooth surface and good printability, often used for packaging with high requirements for appearance, such as dessert boxes.

-

Plastic Materials: Polystyrene (PS) and polypropylene (PP) are often used. PS is lightweight and has good insulation properties, suitable for packaging hot drinks. PP is heat-resistant and moisture-resistant, commonly used for packaging fried foods and salads.

-

Composite Materials: Some packaging boxes use composite materials that combine the advantages of different materials, such as paper-plastic composites. These materials can provide better protection for food and meet different functional requirements.

Printing

-

Offset Printing: This is a widely used printing method. The image on the printing plate is transferred to the rubber blanket and then onto the packaging material. It can achieve high-definition printing effects and is suitable for large-scale production. It is often used to print complex patterns, logos and text on packaging boxes.

-

Flexographic Printing: In flexographic printing, a flexible printing plate is used. It is characterized by high printing efficiency and is suitable for printing on various materials, especially paper and plastic. It is often used for packaging boxes that require fast production and have relatively simple printing patterns.

-

Digital Printing: Digital printing is suitable for small-batch production and personalized packaging. It can directly print digital images onto the packaging material without the need for a printing plate, enabling quick production and easy customization. For example, some limited-edition fast food packaging boxes may use digital printing.

Molding

-

Cutting: After printing, the packaging materials are cut into the required size and shape by cutting machines. There are two common cutting methods: die cutting and laser cutting. Die cutting uses a die to cut the material, which is suitable for large-scale production. Laser cutting uses a laser beam to cut the material with high precision and can cut complex shapes.

-

Folding and Gluing: The cut materials are folded along the pre-designed crease lines to form the shape of the box. Glue or adhesive tape is then used to bond the edges to form a complete packaging box. Some packaging boxes may also use staples or other fastening methods.

-

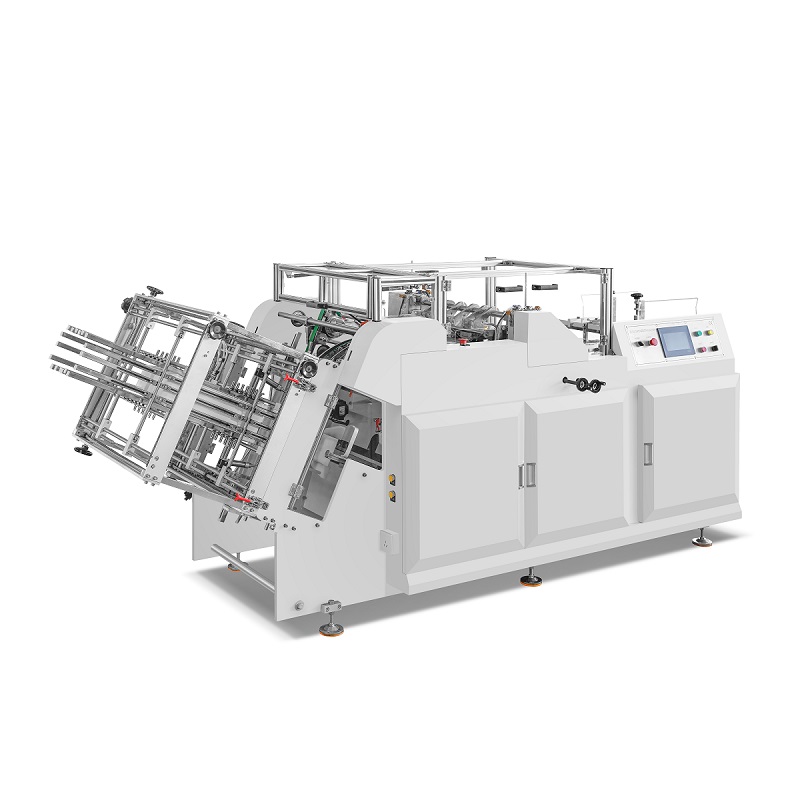

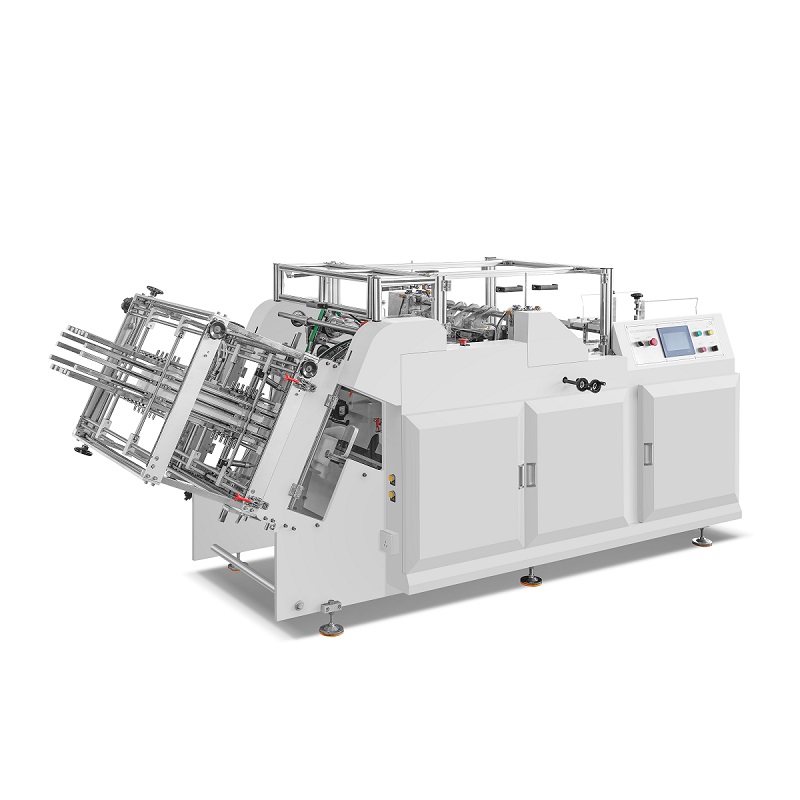

Assembly: For some complex packaging boxes, some additional components need to be assembled. This may involve manual or automatic assembly processes to ensure that all components are installed correctly. This step will use our company's fast food box making machine. Our equipment has a solid structure, high quality, low noise and high efficiency. It has a paper feeding unit, an adjustment unit, a gluing unit, a molding unit, a finished product collection unit, and a counting unit. It is an ideal choice for enterprises

Quality Inspection

-

Visual Inspection: Workers check the packaging boxes for printing quality, including whether the colors are accurate, whether there are smudges or scratches, and whether the text and patterns are clear. They also check the appearance of the box for any damage, deformation or incomplete gluing.

-

Physical Property Testing: The physical properties of the packaging boxes are tested, including their strength, stiffness and moisture resistance. For example, the compression resistance of the box is tested to ensure that it can withstand a certain weight of food during transportation and storage.

-

Function Testing: If the packaging box has special functions, such as heat preservation or leak prevention, relevant function tests are carried out. For example, a leak-proof test is conducted on a sauce packaging box to ensure that the sauce does not leak out.

Packaging and Shipment

-

Packaging: The qualified packaging boxes are stacked and packaged in bulk, usually using cartons or plastic bags for packaging to facilitate transportation and storage.

-

Shipment: The packaged packaging boxes are transported to fast food restaurants or distribution centers by truck, train or other means of transportation. During transportation, care must be taken to avoid damage to the packaging boxes caused by moisture, impact and other factors.

In conclusion, the production of fast food packaging boxes is a complex process that requires the coordination of multiple processes and strict quality control to ensure that the final packaging boxes can not only protect the food well, but also meet the needs of the brand's image display and marketing.