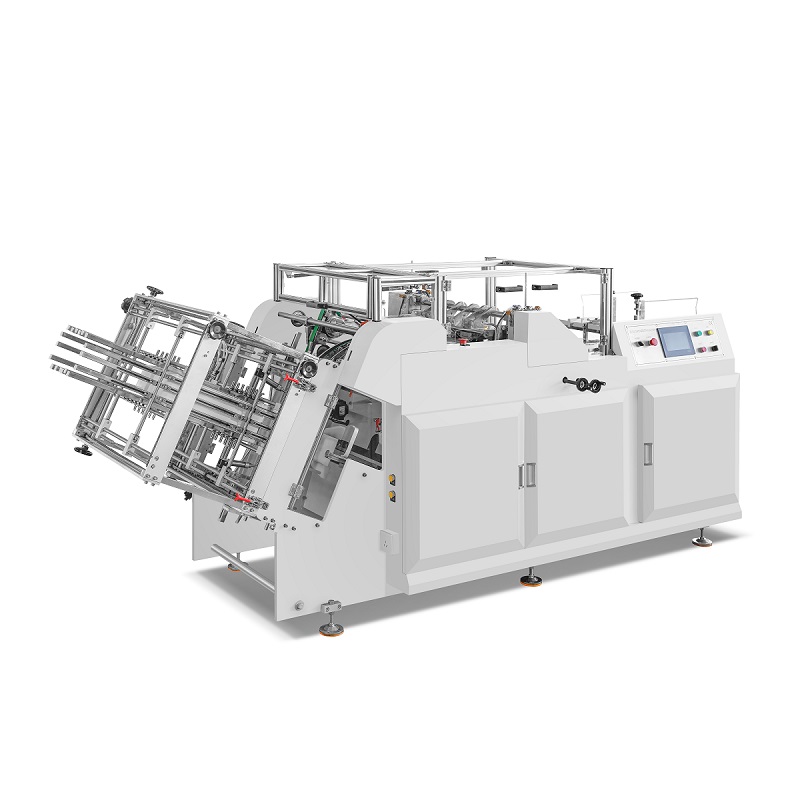

In the flourishing baking industry nowadays, cakes, as much-loved desserts, their packaging is of great significance. A high-quality cake box not only protects the integrity of the cake but also enhances the overall image of the product, attracting consumers' attention. The emergence of the cake box making machine provides an efficient and convenient packaging solution for baking enterprises and packaging manufacturers.

Working Principle and Technical Core

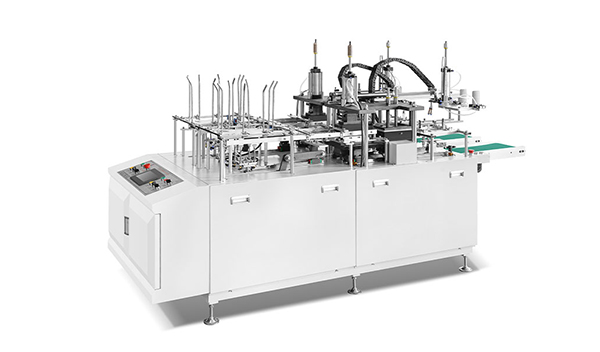

The cake box making machine utilizes advanced automation technology to transform paper raw materials into exquisite cake boxes through a series of precise mechanical operations. Its core technologies include precise paper cutting, accurate folding and shaping, and firm edge sealing. Through pre-programmed procedures, the machine can automatically complete the whole process from paper feeding to finished product output, greatly reducing manual intervention and improving production efficiency and product quality stability.

For example, some high-end cake box making machines adopt advanced sensor technology to monitor the paper feeding and processing status in real time. Once an abnormality occurs, the machine will automatically stop and send out an alarm to ensure the smooth progress of the production process. Meanwhile, the intelligent control system can quickly adjust production parameters according to different cake sizes and shapes, enabling customized production.

Notable Advantages

-

High-efficiency Production: The traditional manual method of making cake boxes is inefficient and difficult to meet the needs of large-scale production. In contrast, the cake box making machine, with its high-speed production capacity, can produce hundreds or even thousands of cake boxes per hour, greatly shortening the production cycle and increasing the enterprise's production capacity. Especially during the baking peak season, it can easily handle a large number of orders.

-

Cost Saving: Although the purchase of a cake box making machine requires a certain initial investment, in the long run, it can significantly reduce production costs. On the one hand, automated production reduces the reliance on a large number of manual workers, reducing labor costs. On the other hand, the precise cutting of raw materials and the efficient production process reduce paper waste, further reducing raw material costs.

-

Stable Quality: The cake boxes produced by the machine have a high degree of consistency in size accuracy, folding angle and edge sealing firmness, ensuring that the quality of each cake box meets high standards. Compared with manual production, machine production can effectively avoid quality differences caused by human factors and enhance the overall quality of products and brand image.

-

Customization Capability: Modern cake box making machines have powerful customization functions and can produce cake boxes of various sizes, shapes and patterns according to different customer needs. Whether it is a square, round or special-shaped cake box, or a customized box with the enterprise's exclusive logo and exquisite patterns, it can be easily realized to meet the diverse needs of the market.

Application Scenarios

Cake box making machines are widely used in various baking enterprises, food packaging factories and the gift packaging industry. For baking enterprises, having their own cake box making machines can not only ensure the timely supply of packaging but also carry out personalized designs according to their own product characteristics, enhancing brand recognition. Food packaging factories can use cake box making machines to provide professional packaging services for many baking enterprises, expanding their business scope. In the gift packaging industry, exquisite customized cake boxes are also often used to package high-end pastries, chocolates and other gifts, increasing the added value of the gifts.

Market Prospects and Development Trends

With the continuous improvement of consumers' requirements for the quality and packaging of baked products and the continuous expansion of the baking industry market scale, the market demand for cake box making machines will also continue to grow. In the future, cake box making machines will develop in the direction of being more intelligent, efficient and environmentally friendly. For example, the adoption of more advanced artificial intelligence technology to realize fully automatic monitoring and fault diagnosis of the production process; the research and development of more energy-saving and environmentally friendly production processes to reduce energy consumption and environmental pollution; and continuous innovation in design to introduce more functional and stylish cake box making machines to meet the increasingly diverse needs of the market.

In conclusion, as an important equipment for baking industry packaging, the cake box making machine, with its advantages of high efficiency, precision and customization, has brought many conveniences and economic benefits to enterprises. In the future development, it will continue to play an important role in promoting the continuous improvement of the baking industry packaging level.