1. Introduction to Paper Boxes

Paper boxes are ubiquitous in our daily lives. They serve as a primary means of packaging for a wide variety of products, ranging from consumer goods like cosmetics and food to industrial products and electronics. A well - designed paper box not only provides protection to the contents but also acts as a marketing tool, enhancing the product's visual appeal and brand identity.

2. Types of Paper Boxes

-

Folding Cartons:

-

These are the most common type of paper boxes. They are flat - packed and can be easily assembled. Folding cartons are usually made from a single sheet of paperboard, which is scored and creased to allow for easy folding. They come in a plethora of shapes and sizes and are widely used for packaging products such as cereal boxes, cosmetics, and pharmaceuticals.

-

For example, a typical cereal box is a folding carton. It has a simple rectangular shape with flaps that can be folded to form the top and bottom of the box. The design on the outside of the box is often eye - catching, with vibrant colors and product information to attract consumers.

-

-

Food Boxes:

-

It has the highest level of safety, has moderate air permeability, and has enough strength to withstand the weight of food and the pressure during transportation and storage.

-

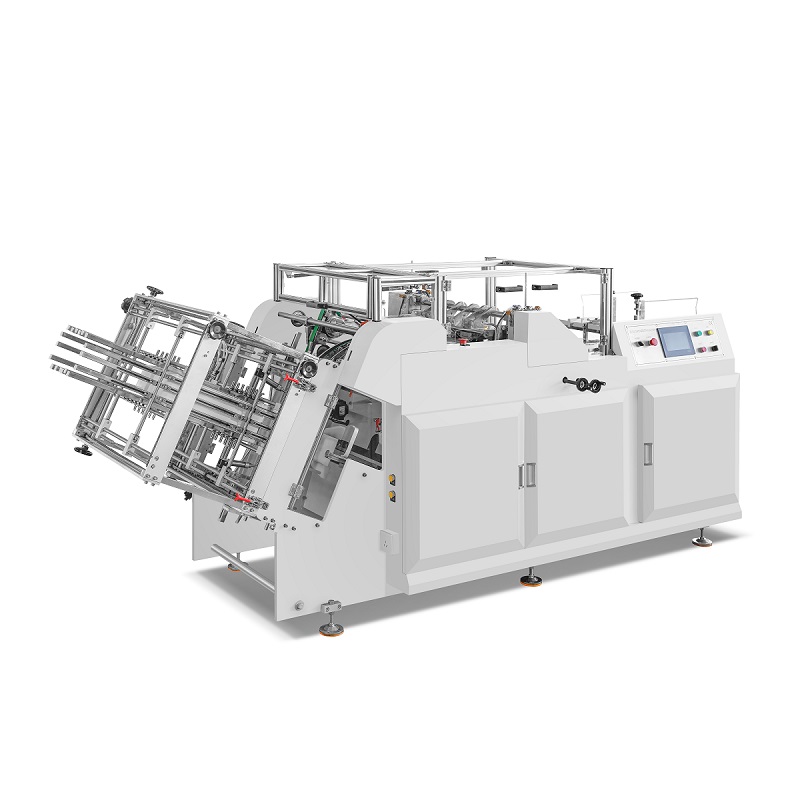

We are a fully automatic carton forming equipment manufacturing company integrating machinery research and development, intelligent manufacturing, and marketing. The company's main product is a fully automatic three-dimensional carton forming machine. If you need, please contact us to learn more.

3. Materials Used in Paper Box Manufacturing

-

Paperboard:

-

Paperboard is the primary material for most paper boxes. It comes in different grades and thicknesses. The choice of paperboard depends on the requirements of the box, such as its strength, durability, and the type of product it will hold. For instance, a heavier - duty paperboard might be used for a box that needs to support a heavy item like a set of books, while a thinner, more flexible paperboard could be suitable for a box of lightweight cosmetics.

-

Recycled paperboard is also becoming increasingly popular due to its environmental benefits. It can be used to create a wide range of boxes, from simple packaging to more elaborate designs, while reducing the impact on natural resources.

-

-

Coatings and Laminates:

-

To enhance the appearance and functionality of paper boxes, various coatings and laminates are used. A gloss coating can give a shiny, attractive finish to the box, making it more visually appealing. Matte coatings, on the other hand, provide a more subdued, elegant look. Laminates can offer additional protection against moisture, abrasion, and other environmental factors.

-

For example, a food box might have a laminate that provides a barrier against grease and moisture, keeping the food fresh and the box in good condition.

-

4. The Manufacturing Process of Paper Boxes

-

Design and Pre - press:

-

The process begins with the design of the box. Designers use specialized software to create the layout, taking into account the size, shape, and functionality of the box, as well as the branding and product information that needs to be displayed. Once the design is finalized, it goes through a pre - press stage, where the graphics are prepared for printing. This includes processes such as color separation and plate - making.

-

For a new product launch, the design team might spend weeks perfecting the look of the paper box, ensuring that it stands out on the store shelf and effectively communicates the product's key features.

-

-

Printing:

-

Printing is a crucial step in paper box manufacturing. There are several printing methods available, including offset printing, flexographic printing, and digital printing. Offset printing is known for its high - quality output and is often used for large - volume production of paper boxes with complex designs and vibrant colors. Flexographic printing is a more cost - effective option for simple designs and large - scale runs, while digital printing offers quick turnaround times and is ideal for short - run or customized orders.

-

A company producing a limited - edition product might choose digital printing to quickly produce a small batch of uniquely designed paper boxes.

-

-

Die - cutting and Creasing:

-

After printing, the paperboard is sent through a die - cutting and creasing machine. Die - cutting shapes the box according to the designed pattern, cutting out the individual panels and flaps. Creasing creates the folds that allow the box to be assembled easily. This process requires precision to ensure that the box fits together properly and has a clean, professional appearance.

-

In a packaging factory, the die - cutting and creasing machines operate at high speeds, producing thousands of accurately cut and creased paperboard pieces per hour.

-

-

Gluing and Assembly:

-

The final step in the manufacturing process is gluing and assembly. The cut and creased paperboard pieces are fed through a gluing machine, where the appropriate flaps are glued together to form the box. Some boxes may also have additional components, such as inserts or partitions, which are added during this stage.

-

For example, a box for a set of delicate glassware might have custom - made inserts to hold each piece securely in place.

-

5. Environmental Impact and Sustainability of Paper Boxes

-

Recyclability:

-

One of the major advantages of paper boxes is their recyclability. Most paper boxes can be recycled and turned into new paper products, reducing waste and the need for virgin materials. Recycling paper boxes helps conserve natural resources such as trees and water, and also reduces energy consumption compared to producing new paper from scratch.

-

Many municipalities have recycling programs that encourage consumers to recycle paper boxes. Some companies also take steps to make their packaging more recyclable, such as using easily removable labels and adhesives.

-

-

Sustainable Sourcing:

-

The paper industry is increasingly focusing on sustainable sourcing of raw materials. Many paper mills now source their wood pulp from sustainably managed forests, ensuring that the production of paper boxes has a minimal impact on the environment. Additionally, the use of recycled paperboard is a key aspect of sustainable packaging.

-

Some companies are even going a step further and using alternative, more sustainable materials such as bamboo - based paperboard or paper made from agricultural waste.

-

6. Applications of Paper Boxes in Different Industries

-

Food and Beverage Industry:

-

Paper boxes are extensively used in the food and beverage industry for packaging a wide range of products. They provide protection from physical damage, light, and moisture, helping to maintain the freshness and quality of the food. From cereal boxes to pizza boxes and juice cartons, paper boxes are an essential part of the food packaging landscape.

-

A pizza box, for example, is designed to keep the pizza warm, prevent it from getting soggy, and also display the brand and product information clearly.

-

-

Cosmetics and Personal Care Industry:

-

In the cosmetics and personal care industry, paper boxes are used to package products such as lipsticks, creams, and perfumes. The boxes not only protect the products but also enhance their visual appeal, with luxurious designs and finishes that attract consumers. A high - end lipstick box might have a glossy finish, embossed branding, and a magnetic closure to give a sense of luxury.

-

-

Electronics Industry:

-

For electronics products, paper boxes are used to package items such as smartphones, tablets, and headphones. The boxes provide protection during transportation and storage and also serve as a marketing tool. The design of the box often includes product images, technical specifications, and brand logos to help consumers make purchasing decisions.

-

A smartphone box, for example, is usually a rigid box with a well - designed interior to hold the device, accessories, and user manuals.

-

7. Future Trends in Paper Box Manufacturing and Use

-

Smart Packaging:

-

The concept of smart packaging is emerging in the paper box industry. This includes features such as embedded sensors that can monitor the condition of the product inside the box, such as temperature, humidity, or freshness. For example, a food box might have a sensor that changes color if the product is no longer fresh, providing consumers with real - time information.

-

Another aspect of smart packaging is the use of QR codes or NFC (Near Field Communication) tags on paper boxes. These can provide consumers with additional product information, such as ingredients, usage instructions, or even interactive content like videos and augmented reality experiences.

-

-

Minimalist and Sustainable Design:

-

There is a growing trend towards minimalist and sustainable design in paper box packaging. Consumers are increasingly conscious of environmental issues, and companies are responding by creating simpler, more recyclable paper boxes. This includes using fewer colors and materials, reducing waste, and focusing on the essential functionality of the box.

-

A brand might choose to use a simple, unbleached paper box with a single - color print and a natural - fiber closure to convey a message of sustainability and simplicity.

-

Paper boxes play a vital role in packaging and marketing, and with the continuous evolution of manufacturing processes and design trends, they will continue to be an important part of our lives and the global economy.