Cake Box Making Machines for Sushi Trays

In the food packaging industry, innovation often comes from repurposing existing technologies. One such example is the application of cake box making machines in the production of sushi trays. This adaptation has brought about several benefits, revolutionizing the way sushi trays are manufactured.

Cake box making machines are designed with a high level of automation, which can be effectively utilized in sushi tray production. These machines can continuously feed raw materials, such as cardboard or plastic sheets, and perform a series of operations including cutting, folding, and shaping. For instance, an automated cake box making machine can cut the material into the appropriate size for sushi trays, fold the edges to form the tray's structure, and even attach any necessary inserts or dividers at a rapid pace. This automated process significantly reduces the time required for manual labor, allowing for a much higher production output. In a busy sushi restaurant supply chain or a large - scale food packaging factory, the ability to produce a large number of sushi trays in a short time is crucial to meet the market demand.

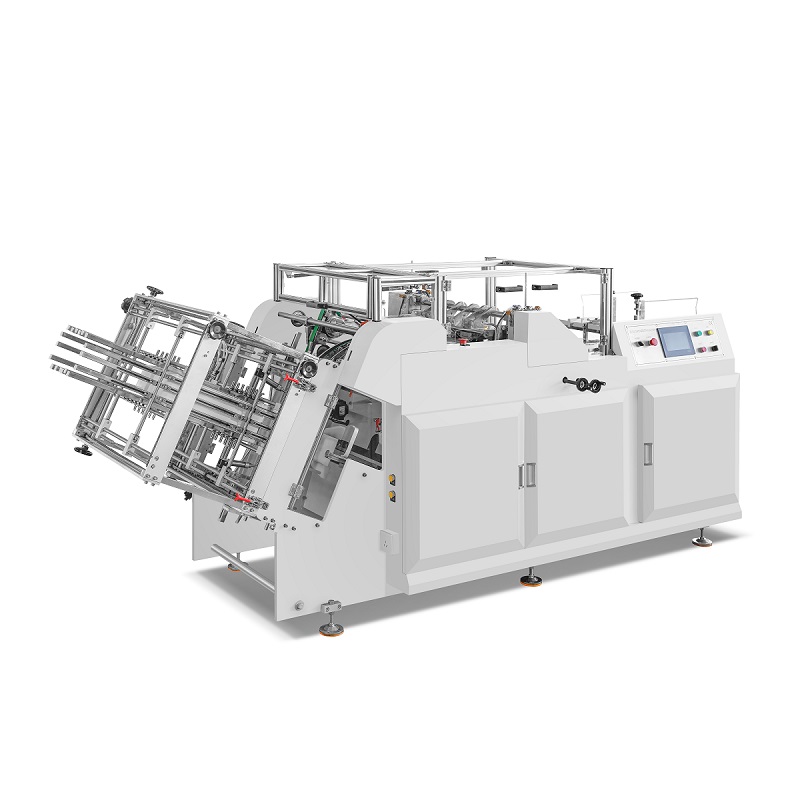

Advantages of Carton Erecting Forming Machine

Servo motor controls the forming die (pressing die) (advanced, more accurate than mechanism cam control)

Adopts full servo system (4 servos in the machine to change the cam system)

Easy to change the die to make different products, charging and adjustment time is very short.

PLC program controls the entire line, which can make complex boxes.

Automatic collection, inventory and counting.

Manually designed control buttons and panels, users work easier and safer.